Dispense Line Integration

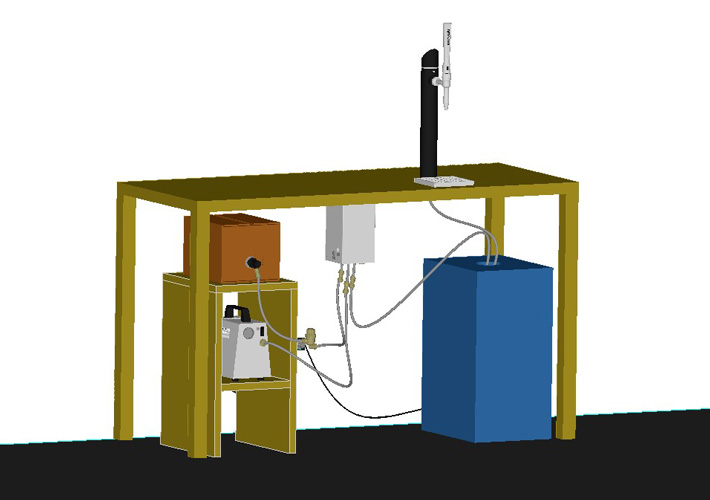

The dispense line integration offers a solution for existing installations with a given cooling infrastructure. As well if only a dispense tower instead of a Nitro-Dispenser is preferred.

Our core components are:

- Nitro-Box

The coffee is pumped from an unpressurized container and pushed through the rest of the pipework under pressure. Compressed air or nitrogen with a pressure of 2.5 bar is used as nitro gas. - Jet-Nozzle spout

The gas is added in the nitro box but the gas/coffee blending takes place in the jet nozzle spout. The spout can be used with existing stout taps.

Required components:

- Product container

Coffee in bag-in-box or canister. Unpressurized containers are preferred but kegs are also possible. - Compressed gas

N2 bottle or oil-free compressed air compressor - Cooling

Dry or water based cooler, refrigerated counter or refrigerator - Nitro-box

This is placed in front of the cooler or in the refrigerated counter/fridge. - Blender

An optional pre-mixer placed after the cooler. Only necessary for very long installations with long distances (up from 5 meters) between Nitro-box and tap. - Dispensing tower

- Stout tap

- Jet-Nozzle spout

Here the final blending of the gas with the coffee takes place.